Concrete Finishing Machine Simulator (VR)

XRVZN’s Concrete Finishing Machine Simulator: Enhancing Worker Safety and Learning

Introduction:

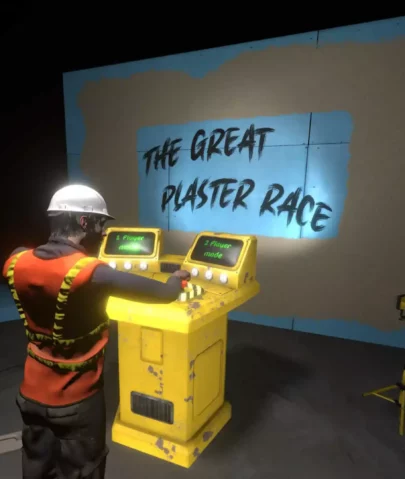

Learning how to operate a ride-on power trowel while on the job can be risky and dangerous, especially for those who are new to the industry. However, the team at XRVZN has developed an innovative solution to this challenge. They have created a fully immersive concrete finishing machine simulator that enables workers to learn how to operate these machines safely and effectively in a virtual environment. The simulator combines a virtual job site with real-world controls, allowing workers to learn how to operate a ride-on power trowel in a risk-free environment.

Challenge:

The challenge for XRVZN was to create a solution that would enable workers to learn how to operate ride-on power trowels safely and effectively in a virtual environment. The team recognized the risks associated with learning on the job, including the potential for accidents and injuries, and set out to design a simulator that would address these challenges.

Solution:

To address the challenge of learning to operate ride-on power trowels safely, XRVZN designed and built a fully immersive simulator. The simulator combines a virtual job site with real-world controls, enabling workers to learn how to operate the machines in a risk-free environment. The simulator was designed with real-world hardware, including the deck and seating, joysticks, and foot pedals, to give workers a realistic experience of operating a ride-on power trowel. XRVZN also used audio transducers, called “butt-kickers,” mounted to the underside of the seat to simulate engine vibrations and obstacle collisions, further enhancing the immersive experience.

Results:

XRVZN’s ride-on power trowel simulator has been successful in enhancing worker safety and learning. Workers can now learn how to operate these machines in a safe and risk-free environment, without the potential for accidents and injuries. The simulator has also been successful in providing workers with a realistic experience of operating a ride-on power trowel, enabling them to develop the skills needed to operate these machines effectively in the real world. The simulator has been well-received by workers, who appreciate the opportunity to learn in a safe and immersive environment, and by employers, who recognize the value of investing in worker training and safety.

Conclusion:

XRVZN’s ride-on power trowel simulator has demonstrated the value of using virtual reality technology to enhance worker safety and learning. By providing workers with a risk-free environment to learn and develop the skills needed to operate ride-on power trowels effectively, XRVZN has helped to reduce the risk of accidents and injuries on the job site. The simulator has also been successful in providing workers with a realistic experience of operating these machines, enabling them to develop the confidence and skills needed to operate them safely and effectively in the real world. XRVZN’s innovative solution has set a new standard for worker training and safety in the construction industry.